The Colorado Study

Energy Conservation vs. Fiberglass

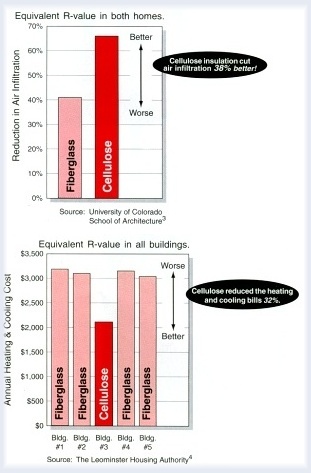

The University of Colorado at Denver School of Architecture and Planning studied the energy conservation efficiency of two test buildings that differed only in the insulation systems that had been installed.

The University of Colorado at Denver School of Architecture and Planning studied the energy conservation efficiency of two test buildings that differed only in the insulation systems that had been installed.

Building “A” was insulated with 5.5 inches of cellulose in the walls and R-30 of loose-fill cellulose in the ceiling. Building “B” received R-19 unfaced fiberglass batts in the walls and R-30 kraft-faced batts in the ceiling.

Over the two-month period a number of different tests and measurements were performed.

Here’s what the University researchers learned.

- In spite of the fact that tests showed Building “B” was about 12% tighter than Building “A” in the uninsulated state, after insulation was installed building “A” was far tighter than “B”. Calculations showed that cellulose tightened the building 36% to 38% more than fiberglass.

- An overnight heat loss test revealed that after nine hours (midnight to 9 a.m.), the cellulose-insulated building was 7 degrees F warmer than the fiberglass building.

- Most significantly, after three weeks of monitoring the cellulose-insulated building had used 26.4% less heat than the fiberglass building.

In their statement of conclusions the researchers note that results suggest cellulose performs as much as 38% better than fiberglass. The performance advantage of cellulose in temperate climates appears to be about 26%, and the report projects that “this benefit would become more significant in more severe climates.”

Cellulose insulation benefits not covered by the University of Colorado study include:

Cellulose insulation benefits not covered by the University of Colorado study include:

- Cellulose contains more than 75% recycled material. In accordance with EPA Guideline 40 CFR Part 248 it is the preferred (and in some cases required) building thermal insulation for projects involving federal funds.

- Since production of cellulose requires much less energy than mineral fiber insulation, which is made in gas-fired furnaces, and foam plastics, which are petrochemicals, the “embodied” energy in cellulose is much lower per “R” of insulating value than other materials. From the national perspective these savings at the production stage must be added to the superiority of cellulose as an insulator.

If you’re serious about saving money heating and cooling your home, about recycling and responsible use of resources, and about saving energy for our country the only insulation to seriously consider is cellulose.

Standards

Cellulose insulation is covered by the most comprehensive legal and voluntary standards of any insulation material. To be sold at all cellulose insulation must meet the requirements of the Consumer Product Safety Commission Safety Standard 16 CFR Part 1209. Most cellulose producers adhere to the much more stringent and comprehensive American Society for Testing and Materials Standard C-739 for loose-fill cellulose insulation and C-1149 for self-supporting spray-applied cellulose insulation. The Federal Trade Commission R-Value Rule applies to cellulose — as it does to all residential thermal insulation.

A number of qualified independent product testing laboratories have cellulose insulation certification programs to assure contractors and consumers that the material they buy and install meets or exceeds government and industry standards. The National Association of Home Builders National Research Center certifies the quality and performance of cellulose insulation.

The labels of underwriters Laboratories, the United States Testing Company, or other NAVLAP-approved laboratories, or the seal of the NAHB National Research Center are reliable indicators of safe, effective cellulose insulation.

If you want insulation that is best for the nation, for the environment, and for your checkbook, choose CELLULOSE!

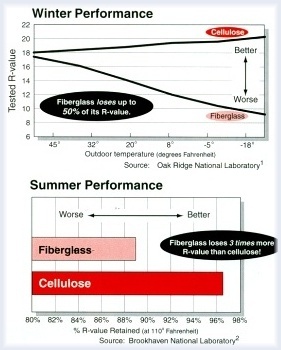

Scientists, engineers, and contractors have realized for many years that the most commonly-used building insulation materials are really not the best insulators. Now this “conventional wisdom” of energy conservation has been confirmed and quantified through scholarly research.

Leave a Reply

You must be logged in to post a comment.